Drum Unloading - Barrel Pump / Drum Pump :- One of the most popular applications of Diaphragm Hand Pumps is in emptying drums, barrel and carboys.It can handle all types of liquids, such as clear liquids, liquids containing solids, latexes (shear sensitive liquids/ thixotropic liquids), slurries, corrosive liquids. It is ideal for handling of inflammable liquids, such as solvents, as its operation is without friction, and hence is suitable for flame-proof plant conditions. It is self priming and requires no special mounting. Just dip suction tube in the barrel and apply handle. It can suck out last drops of liquid from drum. 1” or 1.5” pump is recommended for this duty. It is a low cost substitute for motorized barrel pumps such as Lutz, Graco etc. It can empty a 55 Gallon (200 litres) drums in 8 minutes (1” pump) or 4 minutes (1.5”pump). |

High-Head Transfer Pump :-

Diaphragm Hand Pump is ideally suitable for transfer of liquid directly from barrel to heights of up to 30 feet, and over very long horizontal distances. For transferring to height, 1” model is recommended. This feature is ideally suitable for transfer of water, fuel, chemicals, diesel, kerosene, gasoline etc. It is better substitute for rotary hand pump, piston hand pumps, in operation and in speed. |

In-plant transfer :-

For in-plant transfer duties, Diaphragm Hand Pump offers a simple solution. Just take suction and delivery tubes to respective vessels, and apply handle and the transfer gets done. It is used for siphoning of mother liquor, in intermittent plant duties, in smaller jobs and in batch chemical processes and as emergency standby. When duty conditions match, it forms a low cost substitute/auxiliary/stand-by to chemical process pumps such as Vanton Pump, Fybroc Pump, Durion Pump etc. |

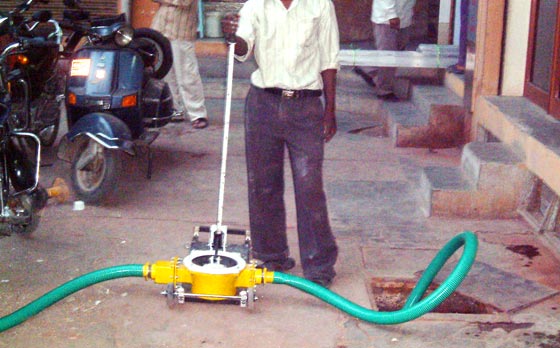

Trash Pump :- Diaphragm Hand Pump handles trash water with ease. It is used for emptying pools, puddles, manholes, clogged drains, sewage tanks, effluents etc. It handles suspended solids with ease. It is a good standby or low cost substitute to Honda Trash Pump, Gorman Rupp Trash Pump, Diesel Trash Pump, where duty conditions are smaller and intermittent. Our 2” model in Cast Iron with Chloroprene diaphragm at 100 LPM (8 ft. suction) is recommended for this service.

|

Effluent Pump :- Handling of effluents in chemical and other industries is easily performed by Diaphragm Hand Pump. In tannery waste management, these pumps work very well due to its non-clog design. In case effluent is acidic in nature, pump in Polypropylene (size 1.5”) at 50 LPM can do the job. In non chemical duties pumps in Cast Iron (size 1.5” or 2”) (at 50 or 100 LPM) are suitable. These pumps form good addition to pollution control plant equipment. They are low cost substitute to Edson Pump, Wilden Pump, Aro Pump, Double Diaphragm Pumps, and Yamada Pumps etc. for duty conditions as above. Many pollution control consultants recommend these pumps as main/ auxiliary/ stand-by equipment. |

Pump For Irrigation :- It can pump water to long horizontal distances, and farms are irrigated without wastage of water in canals. Delivery tube is taken where irrigation is required. Suction tube is put into on-ground water tank. It is ideal for handling of inflammable liquids, such as solvents, as its operation is without friction, and hence is suitable for flame-proof plant conditions. It is a low cost, easy to maintain, substitute/addition/standby to diesel pumps, motorised irrigation water pump, farm irrigation pumps, and forms a necessary part of farm irrigation equipment. It is ideal for dry farming as there is no water loss in canals. It is a preliminary version of drip irrigation system. It is ideally suitable for small farms, third world countries and low cost farming.

|

Pump For Acids And Chemicals :- For handling and dispensing of Acids and corrosive liquids, such as Hydrochloric Acid (HCl), Nitric Acid (up to 50%), Dilute Sulphuric Acid (0-60%), Diaphragm Hand Pump in Polypropylene (PP) is used ( Size 1”-25 LPM, Size 1.5”– 50 LPM). For Conc. Sulphuric Acid 98% pump in Alloy-20 is used (Size 1”-25 LPM). For most of corrosive chemicals, polypropylene is suitable. However, it is advised that details of chemicals, be furnished at enquiry stage itself. Rubber part selection is important, especially for chemicals. For all alkalis, pump in PP/SS316 are suitable. These materials are anticorrosive and hence suitable. Diaphragm Hand Pumps are also used in the chemical process industry, for occasional sampling / injection / dosing / metering pump duty (manually, approximately). |

Pump For Diesel, Gasoline, Fuels :- Diaphragm Hand Pump is used for filling diesel directly to fuel tanks of trucks, earthmoving equipments etc. from barrels. In remote areas, it is a primary fuel filling pump. It empties diesel at 25 litres/minute (1”size). It pumps to heights of up to 30 feet and long horizontal distances. Low cost Cast Iron model with Nitrites (Buna-N) rubber parts is suitable. This pump handles all oils including furnace oils, lubricating oils, waste and burnt oils etc. It is a low cost and simple substitute for rotary barrel pump, diesel barrel pump, drum pumps, hand pumps etc.

|

Mud Pump :- Diaphragm Hand Pumps are used for emptying mud water with suspended solids and dewatering jobs, from pits, construction sites and manholes. ng of inflammable liquids, such as solvents, as its operation is without friction, and hence is suitable for flame-proof plant conditions. For smaller and intermittent jobs they are a preferred choice than diesel mud pumps, Garden Denver Mud Pumps, Mud Hog Pumps and other Waste Water Pumps. Our 2” model in Cast Iron at 100 LPM with Chloroprene diaphragm is recommended for this duty. |

Pump For Sensitive Liquids :- There are many liquids, such as rubber latex solution, liquids with delicate solids, which if pumped by other pumps, such as centrifugal pump, get damaged due to its shear-sensitivity (thixotropic liquids). Diaphragm Hand Pump handles such liquids without damage, as liquid is sucked in and out without churning and shear action of a centrifugal pump.

|

Pump For Bio Gas Plants :- Diaphragm Hand Pumps are extensively used for handling of cattle manure slurry (known as gobar in India), in dairy farms. These pumps are used for feeding slurry to Bio Gas Plant’s anaerobic digester. For injecting slurry into digester under pressure of methane gas, these pumps are used. Low cost Cast Iron pumps of 1” and 1.5” are used, with chloroprene rubber parts. Due to their portability, these pumps are popular in handling of cattle manure, cow dung, animal waste, sanitation duty with portable toilets at farms and plantations. They are an ideal addition to Bio-Gas Plants, Gobar Gas Plants, Methane Digesters and all types of anaerobic digesters. |

Pump For Essential Oils :- In the manufacture of essential oils and natural oils, duty conditions are such that raw essential oils consists of plant leaves, seeds, vegetable skins and like, which are easily handled by Diaphragm Hand Pumps. All types of raw Essential Oils, crude Essential Oils, Natural Oils, Aroma Therapy Oils, bulk essential oils, are handled by Diaphragm Hand Pump. Models in SS 316 with EPDM/Viton rubber parts do this job. These pumps are used by Essential Oil extractors and distillers. |

Pump For Food And Milk products :- Diaphragm Hand Pumps, in Stainless Steel 316, with Silicone rubber Diaphragm and Flap Valves, are extensively used in handling of milk, milk products, molten butter etc.. Vegetable oils, burnt frying oils (food grade silicone rubber parts withstand high temperatures of hot frying oils) are handled by these pumps. Other food items such as gravies, honey, sugar syrups, fruit juice, tomato juice and pulp, grape juice, beverages are handled by these pumps. These pumps can be easily cleaned with water without opening and are hygienic in design and MOC. Diaphragm Hand Pumps are good addition to dairy equipment, food processing machinery, bee farming equipment, large kitchens and wine yards. 1” size is recommended for clear liquids and 1.5” size is recommended for liquids such as gravies with large solids. In food industry, it is used for transferring such liquids from one vessel to another, such as emptying burnt oil from frying vessel. |

Pump For Abbrasive Liquids, Machine Coolants :- There are duties, such as cleaning of grinding machine coolant tank, tank of machines such as CNC lathes, where liquid is full of emery, metal turnings and abrasives. Diaphragm Hand Pump does this job easily, as it simply sucks and pushes out abrasive liquid without churning/clogging. Low cost Cast Iron pumps (1” or 1.5) with Nitrile (Buna-N) rubber parts are used for this application. |

Comparison With Other Types Of Hand Pumps :- There are various types of hand pumps available, such as Cast Iron Hand Pump, Cast Iron Hand Water Pump, Chemical Hand Pump, Fuel Hand Pump, Gasoline Hand Pump, Hand Drum Pump, Hand Operated Pump, Rotary Hand Pump, Semi Rotary Hand Pumps Whenever duty conditions are achievable, Diaphragm Hand Pumps have inherent advantage of simple design, portability, ability to handle all types of liquids, such as clear liquids, slurries, viscous liquids, chemicals etc. |

Sizes Offered In Different M.O.C :-

B: Sizes and typical end use :

C: The final selection of size is to be done by considering: 1. MOC availability 2. Head (Height) to which pumping is to be done 3. Capacity required 4. Cost, in that order of priority. |